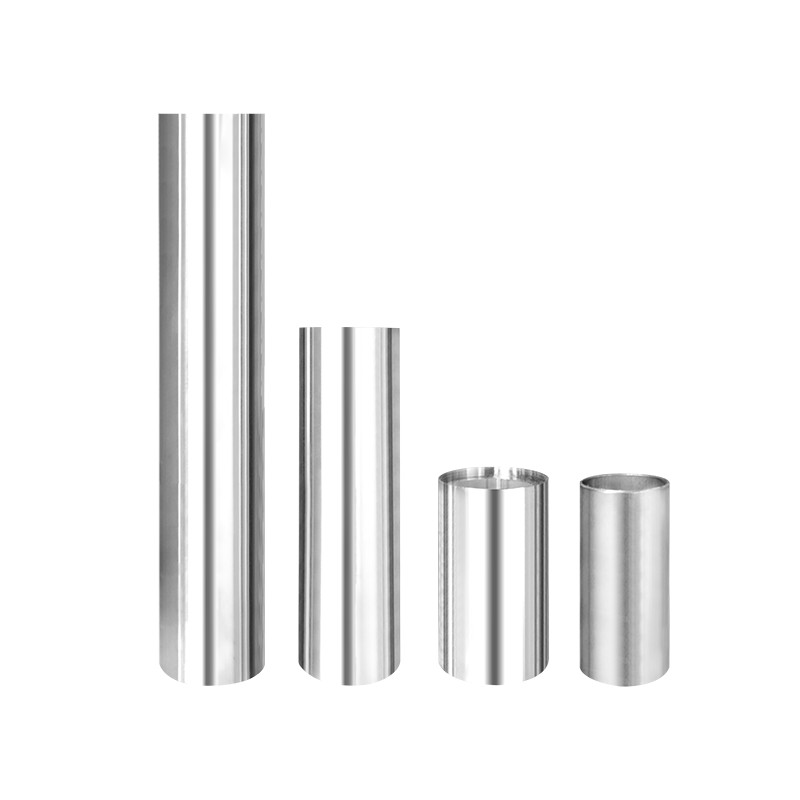

Bright Annealed Stainless Steel Welded Pipe: Precision, Purity, and Performance

2025-08-04

Bright Annealed Stainless Steel Welded Pipe is a vital material across many industries due to its high corrosion resistance, smooth internal finish, and structural integrity. Whether applied in pharmaceutical piping systems, cleanroom gas lines, or chemical processing, it offers unmatched precision and durability.

Zhejiang HengDi Stainless Steel Co., Ltd. is proud to provide high-quality Bright Annealed Stainless Steel Welded Pipes tailored to meet strict international standards, offering optimal results for demanding industrial applications.

What Is a Bright Annealed Stainless Steel Welded Pipe?

A Bright Annealed Stainless Steel Welded Pipe is produced through precision forming and welding processes, followed by bright annealing in a controlled atmosphere furnace. This heat treatment enhances corrosion resistance, improves mechanical properties, and ensures a mirror-like finish on the internal and external surfaces of the pipe.

This pipe type is typically used where hygiene, high purity, and cleanliness are non-negotiable — such as in food processing, biotech, semiconductor manufacturing, and more.

Key Features of Our Bright Annealed Stainless Steel Welded Pipe

-

Superior Surface Finish: Bright annealing creates a highly reflective and smooth surface with Ra ≤ 0.4 μm.

-

Corrosion Resistance: Outstanding resistance to oxidation and a wide range of chemicals.

-

Clean Welding Seams: High-quality automated TIG welding with no filler materials.

-

Dimensional Accuracy: Tight tolerances ensure perfect fit and easy integration.

-

Low Carbon Content: Enhances weldability and reduces intergranular corrosion risk.

-

Available in Multiple Grades: Including 304, 316L, 321, etc.

Technical Specifications

| Parameter | Specification |

|---|---|

| Product Name | Bright Annealed Stainless Steel Welded Pipe |

| Outside Diameter Range | 6 mm – 114 mm |

| Wall Thickness | 0.5 mm – 3.0 mm |

| Standard Length | 6 meters (custom lengths available) |

| Steel Grades | 304, 304L, 316L, 321 |

| Surface Finish | Bright Annealed (BA) |

| Surface Roughness (Ra) | ≤ 0.4 μm (internal), ≤ 0.8 μm (external) |

| Welding Method | TIG (Tungsten Inert Gas), automatic internal bead removal |

| Heat Treatment | Bright Annealed in 100% Hydrogen Atmosphere |

| Compliance Standards | ASTM A269, A270, DIN 11850, ISO 2037 |

| Tolerance | ±0.05 mm (OD), ±10% (wall thickness) |

| Pressure Rating | Based on wall thickness and diameter (available upon request) |

Available Dimensions

| Outside Diameter (mm) | Wall Thickness (mm) | Common Usage |

|---|---|---|

| 6 – 12.7 | 0.5 – 1.0 | Instrumentation, Gas Delivery |

| 13 – 25.4 | 0.7 – 1.5 | Food Grade Systems, Lab Use |

| 26 – 50.8 | 1.0 – 2.0 | Biotech, Cleanroom Distribution |

| 51 – 114 | 1.5 – 3.0 | Structural Support, Process Lines |

Custom sizes, polishing, and fittings are available upon request.

Why Choose Zhejiang HengDi Stainless Steel Co., Ltd.?

-

20+ Years Manufacturing Expertise

-

Certified ISO 9001:2015 Factory

-

Strict Quality Control: 100% Hydrostatic & Eddy Current Testing

-

Global Export Experience: North America, Europe, Middle East, Asia

-

OEM & ODM Support for Custom Orders

Bright Annealed Stainless Steel Welded Pipe FAQs

Q1: What makes a Bright Annealed Stainless Steel Welded Pipe different from a regular stainless steel pipe?

A1: A Bright Annealed Stainless Steel Welded Pipe undergoes a specific heat treatment in a controlled hydrogen environment. This results in a highly polished surface, superior corrosion resistance, and improved structural integrity compared to regular stainless pipes, which may have oxidized or rough surfaces.

Q2: Can Bright Annealed Stainless Steel Welded Pipe be used for high-purity water systems?

A2: Yes. Due to its extremely smooth internal surface (Ra ≤ 0.4 μm), it reduces contamination and bacterial growth, making it ideal for high-purity water systems in pharmaceuticals, microelectronics, and laboratories. The pipe's integrity and cleanliness are maintained through advanced orbital welding and sanitary fittings.

Q3: How do I ensure compatibility between fittings and Bright Annealed Stainless Steel Welded Pipe?

A3: Compatibility is ensured by adhering to standardized dimensions . Our pipes are produced with strict tolerances, and Zhejiang HengDi offers a full range of matching elbows, tees, reducers, and clamps to guarantee system integrity and easy installation.

How We Guarantee Quality

Every Bright Annealed Stainless Steel Welded Pipe is subjected to a comprehensive inspection process:

-

100% Visual Inspection

-

Eddy Current & Hydrostatic Testing

-

Surface Roughness Measurement

-

Spectral Analysis for Grade Confirmation

-

Welding Seam X-Ray or Ultrasonic Testing (Optional)

We provide Mill Test Certificates with every shipment.

Summary

Bright Annealed Stainless Steel Welded Pipe is an essential solution for industries that require high purity, corrosion resistance, and reliable mechanical properties. Zhejiang HengDi's commitment to quality, customization, and service ensures that your project will benefit from the best stainless steel piping available.

Request a Quote or Contact Us

Interested in sourcing Bright Annealed Stainless Steel Welded Pipe from a trusted supplier? Let us provide you with a detailed quote, free samples, or technical consultation.