How To Protect The PET Film?

2024-04-30

Protecting PET (Polyethylene Terephthalate) film involves several measures to ensure its durability and longevity, especially in applications where it may be exposed to environmental factors or mechanical stress. Here are some ways to protect PET film:

1. Surface Coatings: Apply protective coatings to the surface of the PET film to enhance its resistance to scratching, abrasion, and chemical damage. Coatings such as hard coatings (e.g., silicon dioxide), anti-static coatings, or anti-glare coatings can help improve the durability and performance of the film.

2. Lamination: Laminate the PET film with another layer of protective material, such as a clear polyester or polyethylene layer, to provide additional protection against moisture, UV radiation, and mechanical damage. Lamination can also improve the stiffness and tear resistance of the film.

3. UV Stabilizers: Incorporate UV stabilizers into the PET film formulation to protect against degradation and discoloration caused by exposure to sunlight and UV radiation. UV stabilizers help extend the service life of the film when used in outdoor or high UV exposure applications.

4. Handling and Storage: Handle PET film with care to prevent damage from scratches, creases, or tears. Store the film in a clean, dry environment away from direct sunlight, moisture, and heat sources to minimize the risk of degradation and environmental damage.

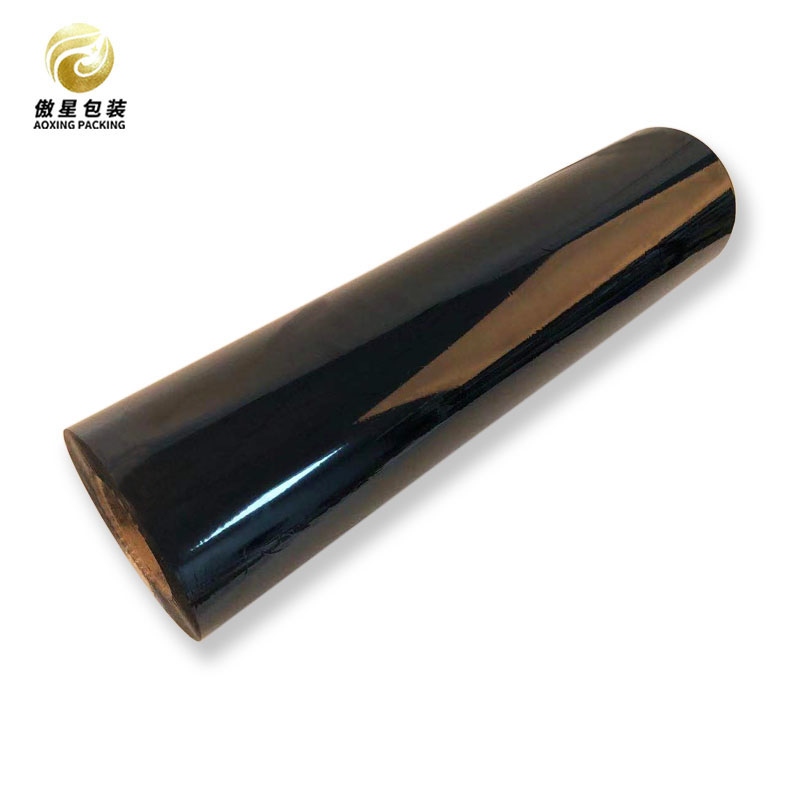

5. Packaging: Use proper packaging materials, such as protective sleeves, bags, or wraps, to protect PET film during transportation and storage. Packaging can help prevent damage from dust, dirt, moisture, and handling during shipping and handling.

6. Cleaning: Clean PET film surfaces regularly using mild detergent solutions and soft, non-abrasive cloths to remove dirt, dust, and residues. Avoid using harsh chemicals, abrasive cleaners, or rough scrubbing tools that could damage the film surface.

7. Edge Protection: Protect the edges of PET film rolls or sheets from damage during handling and processing by using edge protectors, edge seals, or protective tapes. This helps prevent edge chipping, delamination, and mechanical stress that could compromise the integrity of the film.

8. Regular Inspection: Periodically inspect PET film for signs of damage, degradation, or wear, such as scratches, tears, discoloration, or loss of properties. Promptly address any issues identified during inspection to prevent further damage and maintain the quality of the film.

By implementing these protective measures, you can help ensure the durability, performance, and longevity of PET film in various applications, including packaging, labels, graphic overlays, and protective coatings.