The Evolution and Applications of Air Knife Technology

2024-07-25

Introduction

Air knife technology, a vital tool in numerous industries, uses high-velocity streams of air to clean, dry, or cool materials. With its roots in the mid-20th century, air knife technology has evolved to become indispensable in various manufacturing and processing environments. This blog explores the history, mechanisms, and diverse applications of air knives, highlighting their significance in modern industry.

A Brief History of Air Knife Technology

Air knives were first developed in the 1950s, primarily for the coating and paper industries. The early versions were relatively simple, consisting of a slit through which compressed air was forced, creating a high-speed, laminar airflow. Over time, advancements in design and materials have led to more efficient and versatile air knife systems, capable of handling a wide range of industrial tasks.

How Air Knives Work

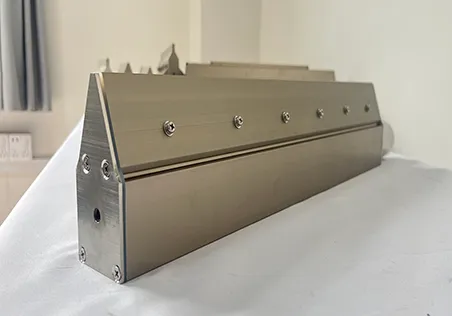

Air knives operate by forcing compressed air through a narrow, elongated slot, creating a high-velocity sheet of air. This air stream can be directed at various angles and pressures, depending on the application. The key components of an air knife system include:

1. Air Source: Typically, a blower or compressed air system provides the necessary air pressure.

2. Knife Body: The body, often made from aluminum or stainless steel, houses the air slot and directs the airflow.

3. Air Slot: A precisely engineered slit ensures a uniform and high-velocity air stream.

4. Control Systems: Modern air knives often feature advanced control systems to regulate airflow, pressure, and direction.

Applications of Air Knives

1. Drying and Cleaning: In industries like automotive and electronics manufacturing, air knives are used to remove water, dust, and debris from surfaces. They are particularly effective in drying conveyor belts, packaging materials, and finished products.

2. Cooling: Air knives can rapidly cool products in industries such as food processing and metal fabrication. By directing a stream of cool air onto hot surfaces, they help maintain product quality and prevent damage.

3. Coating and Laminating: In the coating and laminating industries, air knives ensure even application of coatings by removing excess liquid and creating a uniform surface finish.

4. Sheet and Web Control: In paper and film production, air knives stabilize and control the movement of sheets and webs, preventing wrinkles and ensuring consistent quality.

5. Environmental Control: Air knives are used in HVAC systems to create air curtains, which help maintain temperature and humidity levels in controlled environments like clean rooms and food storage areas.

Advantages of Air Knives

- Efficiency: Air knives provide efficient and effective solutions for drying, cleaning, and cooling, reducing the need for manual labor and increasing production speeds.

- Energy Savings: Compared to traditional drying methods, air knives are more energy-efficient, leading to significant cost savings.

- Versatility: With adjustable airflow and pressure, air knives can be tailored to a wide range of applications, making them highly versatile tools in various industries.

- Non-Contact: As a non-contact method, air knives prevent damage to delicate surfaces and materials, ensuring high product quality.

Conclusion

Air knife technology has come a long way since its inception, evolving into a critical tool across multiple industries. Its ability to efficiently dry, clean, cool, and control materials has made it indispensable in modern manufacturing and processing environments. As technology continues to advance, air knives will likely become even more efficient and versatile, further solidifying their role in industrial applications.