Why is the Round Condenser Tube Essential for Efficient Heat Exchange?

2025-08-18

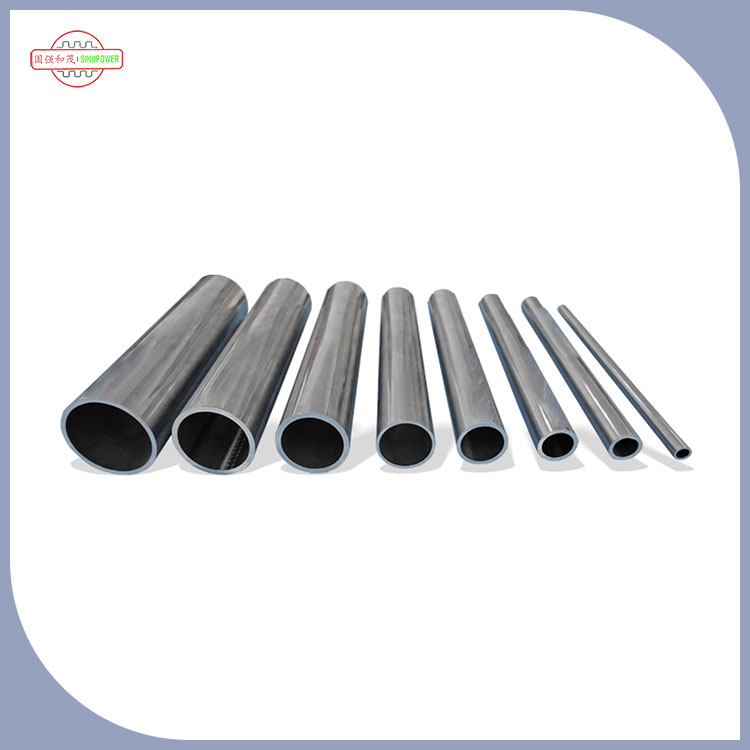

When it comes to heat transfer equipment, one component that consistently proves its importance is the Round Condenser Tube. At Sinupower Heat Transfer Tubes Changshu Ltd., we have spent years refining its design, manufacturing process, and performance to ensure reliability across industries. In this article, I will explore its functions, effectiveness, and overall importance, while sharing my own perspective and answering a few common questions.

The Role of Round Condenser Tube

The Round Condenser Tube plays a critical role in heat exchangers, condensers, and chillers. Its purpose is to efficiently transfer heat from one medium to another, usually from a vapor phase into a liquid phase. By maximizing contact surface while minimizing pressure drop, it ensures smooth operation in various industrial systems.

Key roles include:

-

Facilitating efficient condensation of vapors.

-

Supporting high thermal conductivity with durable metal alloys.

-

Reducing system energy consumption by enhancing heat transfer.

-

Ensuring long-term durability under fluctuating temperatures and pressures.

Usage Effect and Benefits

When I first studied the performance of Round Condenser Tubes in real operations, I was impressed by their ability to enhance system efficiency. Their usage effect is noticeable in both industrial and commercial cooling systems.

Main benefits include:

-

High Efficiency: Faster heat transfer reduces energy usage.

-

Durability: Resistant to corrosion, stress, and erosion.

-

Flexibility: Applicable in power plants, chemical processing, and HVAC systems.

-

Cost-Effectiveness: Long service life reduces replacement frequency.

Importance of Round Condenser Tube

Why is it so important? Without a reliable condenser tube, cooling systems would fail to maintain consistent performance. At Sinupower Heat Transfer Tubes Changshu Ltd., our production process ensures uniform wall thickness, precise diameter, and excellent surface finish—factors that directly improve heat exchange efficiency.

The importance lies in:

-

Industrial Stability – keeping turbines, generators, and process equipment running smoothly.

-

Energy Savings – reducing power consumption in large-scale cooling systems.

-

Safety Assurance – preventing overheating and system failures.

Q&A Section

Q1: Why should I choose a Round Condenser Tube instead of other designs?

A1: In my experience, the round design offers better flow dynamics and higher pressure resistance. It allows me to achieve stable performance in my system with fewer operational issues.

Q2: How can I be sure that the Round Condenser Tube will last long in my application?

A2: Our tubes are manufactured with advanced alloy materials and strict quality checks. I personally trust the durability of our tubes because they are tested under extreme operating conditions.

Q3: What difference will I notice after installing a Round Condenser Tube from Sinupower?

A3: You will notice improved system efficiency, lower maintenance needs, and consistent heat transfer performance. My customers often report reduced energy bills and longer operational cycles.

Technical Data Table

| Feature | Specification | Benefit |

|---|---|---|

| Tube Shape | Round | Optimized flow & high durability |

| Material Options | Copper, Brass, Stainless Steel, Titanium | Corrosion resistance |

| Diameter Range | 6mm – 50mm | Suitable for multiple industries |

| Wall Thickness | 0.5mm – 3mm | Strength under pressure |

| Applications | Condensers, Chillers, Heat Exchangers, HVAC | Wide industry usage |

Contact

The Round Condenser Tube is more than just a component—it is the foundation of reliable heat transfer systems. At Sinupower Heat Transfer Tubes Changshu Ltd., we combine advanced manufacturing with years of expertise to deliver products that help industries achieve higher efficiency and stability.

👉 If you want your system to perform at its best, choose our Round Condenser Tubes—because reliable heat transfer starts with the right tube.